Searching for the ideal module power supply for your specific application can feel like navigating a labyrinth. With a multitude of options available, how do you ensure you choose the right one? Look no further! In this step-by-step guide, we will walk you through the process of selecting the perfect module power supply for your needs.

Understanding the unique requirements of your application is the first crucial step. Whether it’s for industrial machinery, telecommunications equipment, or medical devices, each application demands a specific power supply solution. We will delve into the factors you need to consider when determining the power requirements for your device.

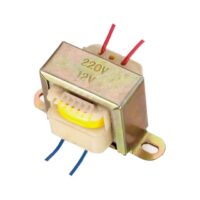

Next, we will explore the various types of module power supplies and their key features. From AC-DC to DC-DC converters, we will help you decipher the differences and choose the most suitable option.

Furthermore, we will discuss the importance of voltage regulation, efficiency, and reliability. These factors not only impact the performance of your application but also directly affect its lifespan.

By the end of this guide, you will possess the knowledge and confidence to select the right module power supply, ensuring optimal performance and longevity for your application. Let’s embark on this journey together and make an informed decision!

Understanding your application’s power requirements

Determining the power requirements of your application is the first crucial step in choosing the right module power supply. Each application has unique demands that must be taken into account. Whether it’s for industrial machinery, telecommunications equipment, or medical devices, understanding the specific power needs is essential.

To determine the power requirements, you need to consider factors such as the operating voltage range, maximum current draw, and any special considerations for peak power demands. Additionally, you should take into account any voltage tolerances and the overall power budget of your application.

Once you have a clear understanding of your application’s power requirements, you can move on to exploring the various types of module power supplies available.

Types of module power supplies

When it comes to module power supplies, there are several different types to choose from. Each type has its own set of characteristics and features that make it suitable for specific applications.

1. AC-DC Power Supplies: These power supplies convert alternating current (AC) from the main power source to direct current (DC) required by your application. They are commonly used in a wide range of applications, including consumer electronics, telecommunications, and industrial equipment.

2. DC-DC Converters: DC-DC converters are designed to convert one DC voltage level to another. They are often used in applications where the input voltage is different from the required output voltage. DC-DC converters are commonly used in battery-powered devices, automotive applications, and renewable energy systems.

3. Linear Regulators: Linear regulators are simple and cost-effective power supplies that provide a stable output voltage. They are commonly used in low-power applications where efficiency is not a primary concern. Linear regulators are often used in audio equipment, sensors, and low-power microcontrollers.

4. Switching Regulators: Switching regulators are highly efficient power supplies that use a switching mechanism to regulate the output voltage. They are suitable for applications that require high efficiency and low power dissipation. Switching regulators are commonly used in high-power applications, such as servers, industrial automation, and LED lighting systems.

Understanding the different types of module power supplies will help you make an informed decision based on the specific requirements of your application.

Factors to consider when choosing a module power supply

Choosing the right module power supply involves considering various factors to ensure optimal performance and reliability. Let’s walk through the step-by-step process of selecting the perfect power supply for your needs.

### Step 1: Determine the input voltage range

The input voltage range is a critical consideration when choosing a module power supply. You need to ensure that the power supply can handle the voltage fluctuations that may occur in your application. It’s essential to consider both the minimum and maximum input voltage requirements to avoid any potential issues.

### Step 2: Calculate the output power requirements

Calculating the output power requirements is crucial to ensure that the power supply can deliver enough power to your application. You need to consider both the continuous power requirements and any peak power demands. It’s important to choose a power supply that can handle the maximum power requirements of your application without overloading or compromising its performance.

### Step 3: Consider efficiency and thermal management

Efficiency is an important factor to consider when choosing a module power supply. Higher efficiency means less power wasted as heat, resulting in better overall performance and lower energy consumption. It’s essential to select a power supply with high efficiency to maximize the energy efficiency of your application.

Thermal management is another critical consideration. Power supplies generate heat during operation, and proper heat dissipation is necessary to ensure the longevity and reliability of your application. Make sure to choose a power supply that includes adequate thermal management features, such as heat sinks or fans, to prevent overheating.

### Step 4: Evaluate the form factor and mounting options

The form factor and mounting options of the module power supply are important considerations, especially if space is limited in your application. You need to ensure that the power supply can physically fit within the available space and that it can be securely mounted. Consider the dimensions, weight, and mounting mechanism of the power supply to ensure compatibility with your application.

### Step 5: Check for safety and regulatory certifications

Safety is paramount when it comes to choosing a module power supply for your application. Look for power supplies that comply with industry safety standards and have undergone rigorous testing and certification. Common certifications to look for include UL, CE, and FCC compliance. Ensuring that the power supply meets these standards will give you peace of mind and ensure the safety of your application.

By following these steps and considering the factors mentioned above, you can confidently choose the right module power supply for your application.

Step 1: Determine the input voltage range

Selecting the right module power supply for your application is crucial for optimal performance and reliability. By understanding your application’s power requirements, exploring the different types of module power supplies, and considering factors such as input voltage range, output power requirements, efficiency, thermal management, form factor, and safety certifications, you can make an informed decision.

Remember, each application is unique, and it’s important to choose a power supply that meets the specific requirements of your application. By following this step-by-step guide, you will be able to navigate the labyrinth of options and select the perfect module power supply, ensuring the best performance and longevity for your application.

Let’s embark on this journey together and make an informed decision!

Step 2: Calculate the output power requirements

The input voltage range for a module power supply is the voltage range that the power supply can accept and convert to a usable output voltage. This range is typically specified on the datasheet for the power supply and can be a critical factor in selecting the right power supply for your application.

When selecting a power supply, it’s essential to choose one that can accept the input voltage of your application. If the input voltage of your application is outside the input voltage range of the power supply, the power supply will not function correctly, and you may damage the power supply or your application.

Additionally, it’s important to consider the maximum and minimum input voltage levels that your application may experience. If your application experiences voltage spikes or drops outside the specified input voltage range, the power supply may shut down or be damaged.

Step 3: Consider efficiency and thermal management

The output power requirements for a module power supply are the power requirements of the load that the power supply will be driving. Calculating the output power requirements for your application is critical to selecting the right power supply.

To calculate the output power requirements for your application, you’ll need to determine the voltage and current requirements of your load. Once you have these values, you can calculate the output power requirements by multiplying the voltage and current requirements together.

It’s important to choose a power supply that can deliver the necessary output power for your application. If the power supply cannot provide enough power, your application may not function correctly, or you may damage the power supply.

Step 4: Evaluate the form factor and mounting options

Efficiency and thermal management are critical factors to consider when selecting a module power supply. The efficiency of a power supply is the ratio of the output power to the input power and is typically expressed as a percentage.

A more efficient power supply means less power is wasted as heat and more power is available for your application. Additionally, a more efficient power supply runs cooler, which can be beneficial for thermal management.

Thermal management is the process of managing the heat generated by your application and the power supply. If your application generates a lot of heat, you may need to consider a power supply with a higher efficiency rating or one with an integrated fan or heatsink.

Step 5: Check for safety and regulatory certifications

The form factor and mounting options of a module power supply can be critical factors in selecting the right power supply for your application. The form factor refers to the physical size and shape of the power supply, while the mounting options refer to how the power supply can be mounted in your application.

It’s important to choose a power supply that fits within the physical constraints of your application. Additionally, if your application requires a specific mounting option, such as a DIN rail mount, you’ll need to ensure that the power supply you select has that option.

Conclusion: Choosing the right module power supply for your application

Safety and regulatory certifications are essential when selecting a module power supply. These certifications ensure that the power supply meets specific safety and performance standards, such as UL, CE, and RoHS.

When selecting a power supply, it’s important to check for the appropriate safety and regulatory certifications for your application. If your application requires a specific certification, such as UL or CE, you’ll need to ensure that the power supply you select has that certification.